Collect flax fiber, flax yarn, flax blended yarn, flax yarn dyeing, flax needle weaving, flax shuttle weaving, flax curtain, flax wall cloth, flax ready-made clothes, etc. to create your own flax life!

one

Trend of regenerated fiber

China will vigorously develop recycled fiber and promote green manufacturing

Xinhua news agency, Beijing, September 5, the reporter learned from the China Chemical Fiber Industry Association on the 5th that China will vigorously develop recycled fiber, polylactic acid fiber and degradable fiber, improve the independent innovation ability and green manufacturing level of the chemical fiber industry, and improve the recycling system.

Chemical fiber is one of the most important materials in industrial production and social life. The green manufacturing level of chemical fiber industry reflects a country's cleaner production capacity. At present, the world chemical fiber industry is accelerating its transformation to a more environmentally friendly and green direction. China is the world's largest chemical fiber producer and consumer. The huge market demand and production scale call for a cleaner and environmentally friendly manufacturing mode.

Gao Yong, Secretary of the Party committee of China Textile Industry Federation, said that through innovation and development, the level of China's recycled cellulose fiber and recycled chemical fiber has been continuously improved, the development of high-performance fiber has made a breakthrough, and the green manufacturing level of the chemical fiber industry has been significantly improved, but the industry still faces great pressure of transformation and upgrading and environmental protection.

Duan Xiaoping, President of China Chemical Fiber Industry Association, said at the 25th China International Chemical fiber conference previously hosted by China Textile Industry Federation that China is accelerating the development and application of green design, green manufacturing and recycling technologies in the chemical fiber industry, further improving the cleaner production evaluation index system and strengthening cleaner production audit and performance evaluation. In the future, we will vigorously develop recycled fiber, new solvent regenerated cellulose fiber, polylactic acid fiber and degradable fiber, accelerate the breakthrough of the bottleneck of existing chemical fiber equipment, meet the production requirements of multi variety, high quality, low energy consumption and cleaning, and comprehensively improve the green manufacturing level of the industry. 02

Global recycling standards certification

Global recycling standard (GRS / RCS)

Global recycling standard for textiles and clothing Global recycle standard (GRS) is a third-party certification standard formulated by the Dutch regulatory Union and implemented since January 2008 for the use of recycled fibers after recycling waste textiles. In January 2011, the Dutch regulatory union transferred the copyright of the global recycling standard of textiles and clothing to the most influential American Textile Fair in the world.

In principle, the new version of GRS certification can meet the conditions for applying for GRS certification as long as 20% of the recycled ingredients are met. From the recycling stage, each production stage must be certified, and finally end with the last seller in the enterprise to enterprise transaction. Material collection and material concentration sites require self declaration, document collection and site visits. In addition, only products with at least 50% recycled content meet the product specific GRS} label.

In order to obtain GRS , certification, all companies involved in manufacturing and operating your products, including semi-finished product suppliers, must also comply with GRS , standards. Global recycled standard (GRS) is an international, voluntary and complete product standard. The content is aimed at the implementation of product recycling, recycled ingredients, regulatory chain control, social responsibility and environmental norms, as well as chemical restrictions by supply chain manufacturers, and is certified by a third-party certification authority.

Access conditions for GRS # certification?

The proportion of recycled components in the product is greater than 20%; If the product plans to hang GRS logo, the proportion of recycled components shall be greater than 50%. Firstly, GRS is traceable. If company a wants to apply for GRS certification, its upstream suppliers also need GRS certification.

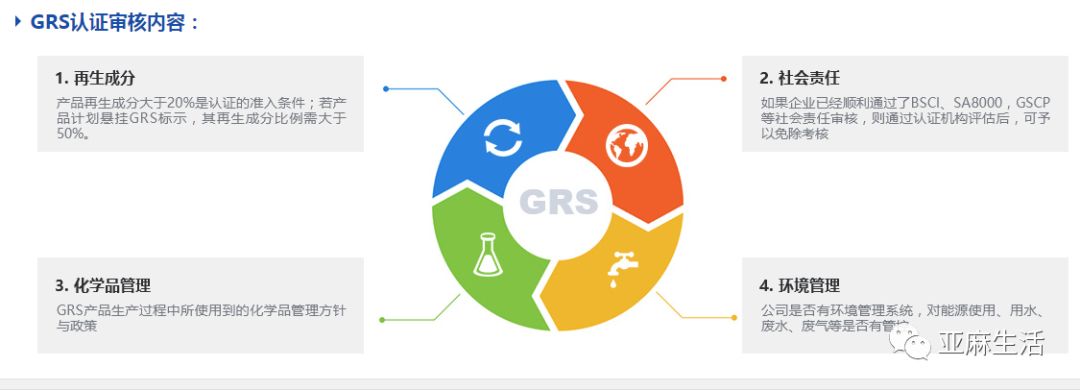

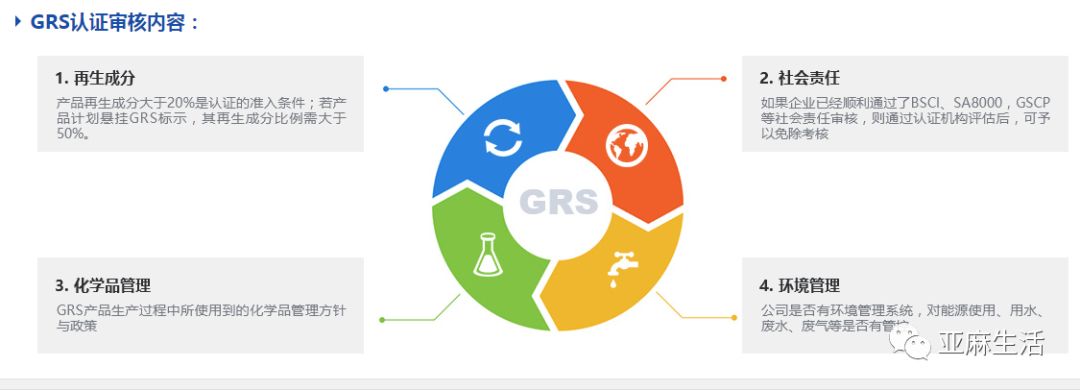

What aspects of GRS / RCS} certification?

GRS # certifies the following 4 # modules:

1. Recycled ingredients: more than 20% of the recycled ingredients of the product is the access condition for certification.

2. Social responsibility: if the enterprise has successfully passed BSCI, SA8000, gscp and other social responsibility audits, it can be exempted from the assessment after passing the assessment of the certification authority.

3 chemical management: chemical management policies used in GRS # product production.

4. Environmental management: whether the company has an environmental management system and whether it has control over energy use, water, wastewater and waste gas. RCS certification is the first mock exam: regenerative ingredients. More than 5% of the product's recycled components are the entry conditions for certification.

What can GRS} certification bring?

The reuse of materials helps to reduce the dependence on non renewable resources, reduce the environmental load caused by waste discharge and waste treatment, and contribute to the sustainable development of society.

The rational utilization of renewable resources has been concerned by more and more brand buyers and consumers. At present, many European and American brands require domestic suppliers to obtain GRS certificate. Without GRS certificate, there will be no cooperation opportunities, and will not be included in the purchase list of international buyers and world famous enterprises.

Products with GRS # certification certificate can be hung with GRS # logo according to relevant regulations of GRS # and brand logo according to relevant regulations of brand manufacturers. It is easier to enter the international stage at both product level and company level.